With the recovery, manufacturers' order books are full but activity is slowing down.

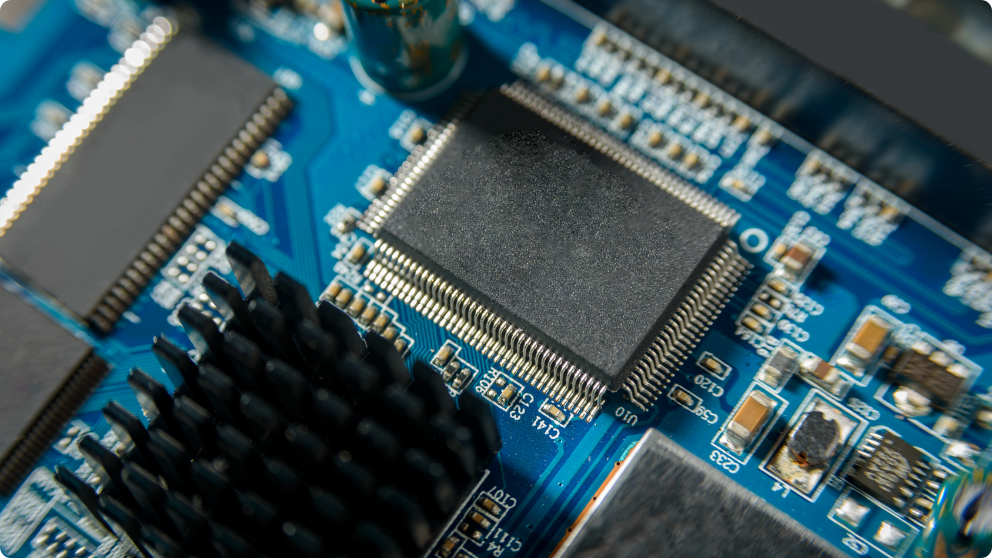

For several months, manufacturers have been suffering from a shortage of components and raw materials. Market tensions and the high demands of global industrial production since the pandemic have created a supply bottleneck that is difficult to overcome.

The shortage has immediate repercussions on many sectors of the economy such as the automotive, construction, mobile phone, IT, food and toy industries.

Many manufacturers are struggling to keep up with production and many shops are dependent on this situation. Faced with product shortages or delivery delays, brands and retailers are finding it difficult to meet demand, with very limited visibility on actual delivery times.

These disruptions inevitably have a knock-on effect on production and transport costs. Logistical penalties continue to increase, becoming a major problem for some companies. Neomag provides some explanations 📰 here

All this leads to a bidding war when it comes to sourcing, even with large volumes of purchases. What is scarce is more expensive. In addition, the scarcity of these raw materials leads to a rise in prices, which has an irreparable impact on the margins of professionals.

This inflationary environment has a direct impact on consumers' wallets, at a time when purchasing power is once again a priority issue for the French.